Below is the consumption of Vehicles for test track. The only variables changed was considering 1 vehicle, 150 meters inbetween stops

|

|||

|

| |||

|

|

|

||

|

6.46103575E+05

|

J/Car

|

||

|

1.60E+04

|

W/Car

|

||

|

1.60E+01

|

Kw/Car

|

||

|

3.82876E+02

|

Kwh Per Day

|

||

|

1.39750E+05

|

Kwh Per Year

|

||

|

Flex-02

350W

|

Symbol

|

Performance

|

|

Nominal Power

|

W

|

350

|

|

Efficiency

|

%

|

13.6559

|

|

Maximum Power Current

|

A

|

11.33

|

|

Open Circuit

Voltage

|

V

|

38.8

|

|

Maximum System Voltage

|

V

|

1000/600

|

|

Area

|

m2

|

2.572

|

|

Weight

|

Kg

|

2.4

|

2300m^2-2800m^2

Below is the cost analysis to satisfy this track (accounting for the Miasole panels) and considering different orientations with their specific optimizations. The Helios activator was assumed when calculating the cost and energy consumption of tracking systems.

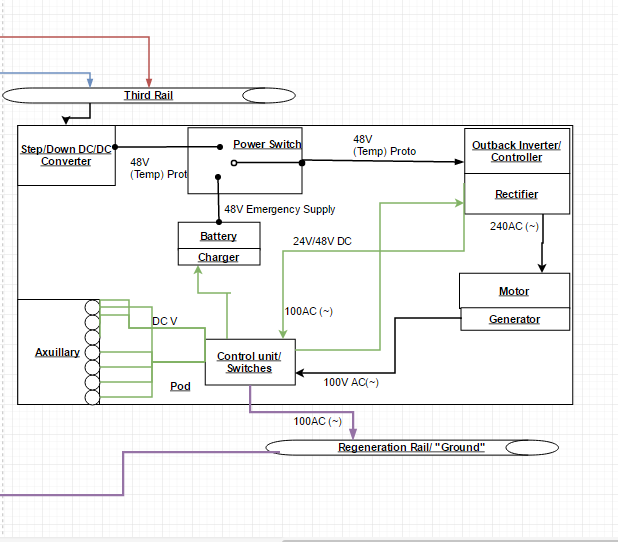

The basic electrical diagram assumes a solar panel

array of 1400 DC voltage which inverts (with the same phase as the grid) to an

1100 AC loading voltage. The 1100 AC loading voltage is then forced through a

control switch and a series of sub-switches depending on where the voltage is

needed in the system. If pods are not consuming all the supplied power, then

the 1100 AC voltage will lead to a step-up transformer to charge the grid

system. If significant power is being drawn by the pods, then the loading

voltage is switched to the Converter/Substation and the 1100 AC voltage

converts to a 750 DC voltage. During non-sunlight hours the Grid will unload

and the assumed 12,000V AC will step-down to an 1100V AC. The outback charger

forces the 1100AC V unloading from the Grid to have the same phase as the

inverter. The 1100 AC voltage unloading is then switched into the

Converter/Substation the same way it would switch when being loaded by the

solar array.

When

the Converter/Substation receives an 1100AC voltage (from the Grid or Solar

Array) it outputs 750 DC voltage directly into the Third Rail of our system.

The third rail is in turn connected to a step-down DC to DC converter. Assuming

that we use an AC motor the converter will be connected to an inverter and the

48DC voltage supplied from the converter will by inverted into a 240AC voltage

that directly powers our motor. The regenerative braking system (motor-generator)

will go into a control unit which will determine where the voltage is needed.

In the case pod components need to be charged, the 100 AC (assumed) voltage

from the motor-generator will go into a rectifier that will convert the 100 AC

voltage into a 12-48V depending on which component needs to be powered. In the

case the Gird and the Solar panels fail, there is a backup emergency battery

that will power the motor; most likely, in this case, the regeneration energy

will go into power the battery. If all components are working optimally

(Battery and Auxiliary) than the control unit will allow the 100AC V to go into

the Regeneration Rail/ “Ground”. Unlike many Three or Four rail systems,

Spartan Superway designed its regeneration rail and ground rail to be the same,

utilizing energy that is lost. The Regeneration would lead into a step-up

transformer and charge our grid, completing the circuit of our system.

No comments:

Post a Comment